Spacing bottom hole pumps

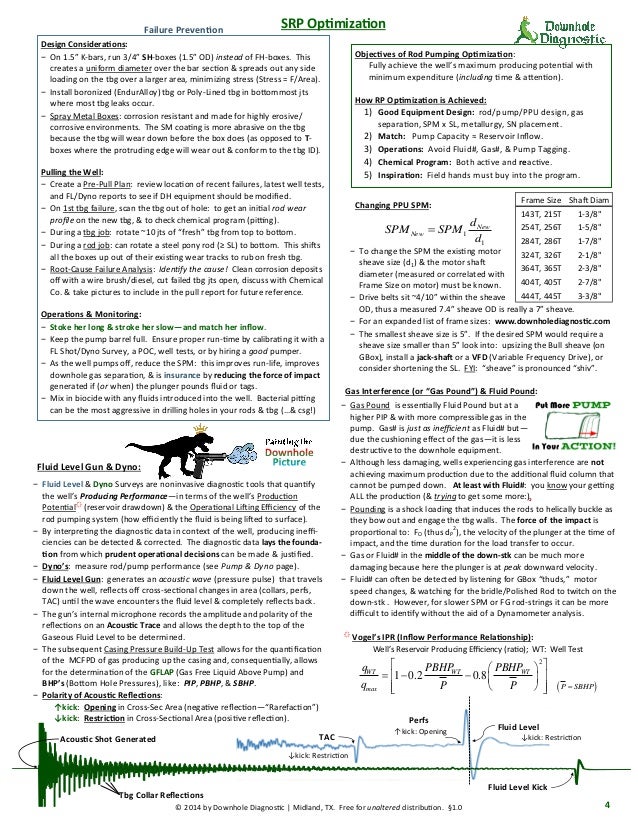

USPTO , USPTO-Zuordnung , Espacenet. Typical values, based on experimental data are about two times greater for plunger fits less than 0. Protect your producers by biocide-treating any fluids introduced into a well including frac jobs. The system of the present invention is completed by providing at the bottom end of the tubing a foot valve or standing valve The plunger and traveling valve are run in the well with the sucker rods. Are you sure you want to Yes No. These changes have incorporated the prior information in API RP 11AR [2] and the NACE International MR [3] for materials to be used in most production environments.

USPTO , USPTO-Zuordnung , Espacenet. Typical values, based on experimental data are about two times greater for plunger fits less than 0. Protect your producers by biocide-treating any fluids introduced into a well including frac jobs. The system of the present invention is completed by providing at the bottom end of the tubing a foot valve or standing valve The plunger and traveling valve are run in the well with the sucker rods. Are you sure you want to Yes No. These changes have incorporated the prior information in API RP 11AR [2] and the NACE International MR [3] for materials to be used in most production environments.

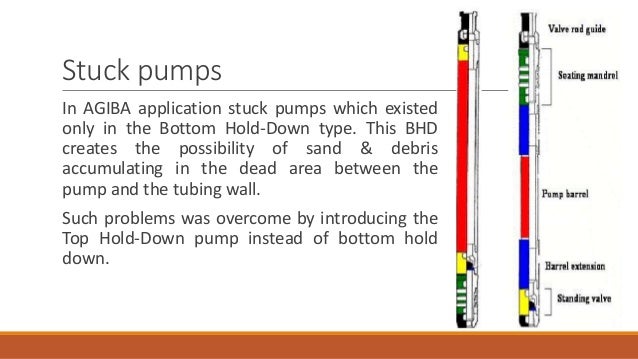

Downhole sucker-rod pumps

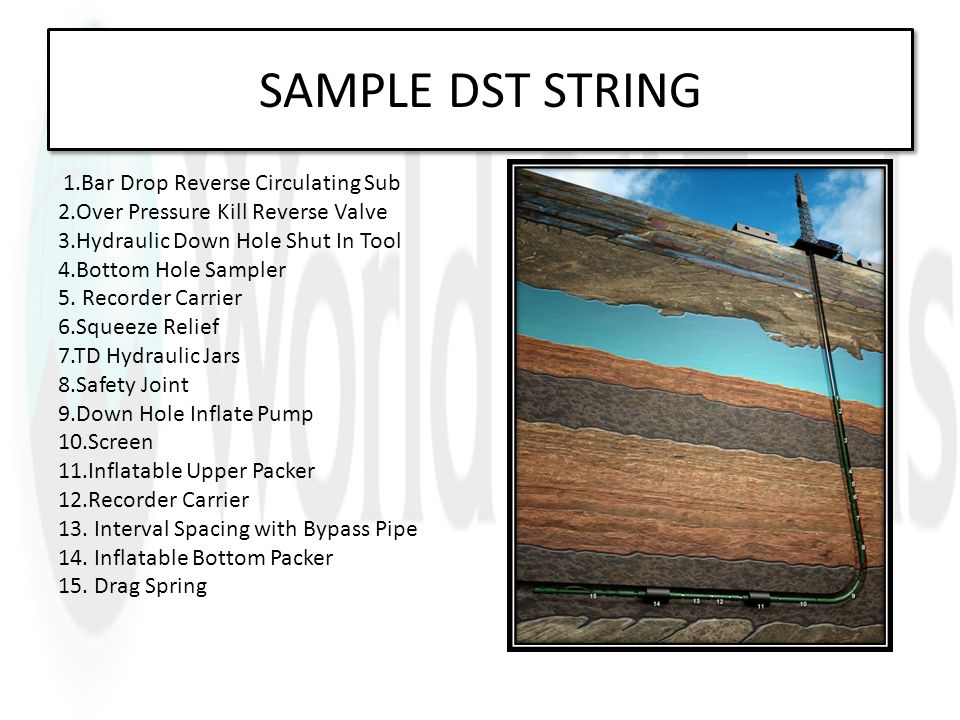

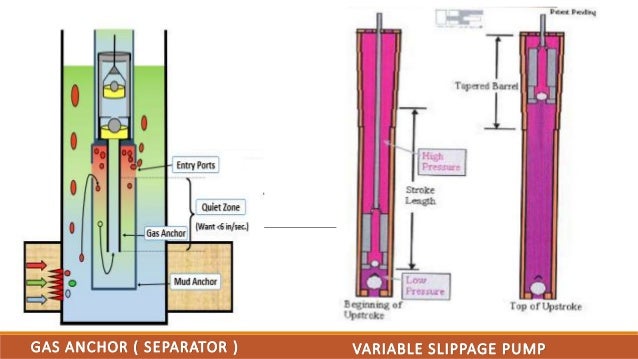

The types of fittings and their respective lengths depend on the type of pump being used. The FRP-rod manufacturer should have, or have access to, a sucker-rod-string design program that will estimate the increased plunger travel. Some manufacturers increase the areas of nozzles and throats in a geometric progression i. In a sucker-rod installation, the rod that actuates the pump plunger extends to the surface of the well and connects to the pumping unit; however, in hydraulic pumps, the rod is quite short and extends only to the engine pistons. This low pressure causes vapor cavities to form, a process called cavitation. The throat and nozzle flow areas define an annular flow passage at the entrance of the throat. The shifting of the engine valve redirects the flow of power fluid to the engine piston and causes the reversal of the rod-and-plunger system.

The types of fittings and their respective lengths depend on the type of pump being used. The FRP-rod manufacturer should have, or have access to, a sucker-rod-string design program that will estimate the increased plunger travel. Some manufacturers increase the areas of nozzles and throats in a geometric progression i. In a sucker-rod installation, the rod that actuates the pump plunger extends to the surface of the well and connects to the pumping unit; however, in hydraulic pumps, the rod is quite short and extends only to the engine pistons. This low pressure causes vapor cavities to form, a process called cavitation. The throat and nozzle flow areas define an annular flow passage at the entrance of the throat. The shifting of the engine valve redirects the flow of power fluid to the engine piston and causes the reversal of the rod-and-plunger system.

Bottom Hole Pump | Webco Industries, Inc.

However, because the nozzle energy is transferred to a large amount of production compared to the power-fluid rate, lower heads will be developed. The pump manufacturer typically machines or obtains subcontract pump components for future assembly of the pump by a pump shop. Finally, if these normal solutions do not resolve the problem, then special pumps or specialty components may be considered. The widespread current use of jet pumps can be credited to the advent of computer programs capable of making the iterative calculations necessary for application design.

Downhole hydraulic pump types

Description: Area ratios greater than 0. The diameter of the throat is always larger than the diameter of the nozzle exit, allowing the well fluids to flow around the power-fluid jet and be entrained by it into the throat. There is a wide range of plunger or pump-bore sizes standardized by the industry. The mixing tube, usually called the throat, is a straight, cylindrical bore about seven diameters long with a smoothed radius at the entrance. The FRP-rod manufacturer should have, or have access to, a sucker-rod-string design program that will estimate the increased plunger travel.

Views: 2492

Date: 20.04.2015

Favorited: 5

User Comments

Post a comment

Comment: